- Brick Making Machinery[25]

- Refractory[19]

- Carbon[2]

- Metal Straightening Machinery[4]

- Mining Machinery[83]

- Sand Making Machinery[20]

- Other Construction Material Making Machinery[10]

- Personal Watercraft[3]

- Building Material Making Machinery Parts[3]

- Grinding Equipment[1]

- Other Petrochemical Related Products[3]

- Crusher[10]

- Mine Mill[10]

- Other Mining Machinery[10]

- Vibrating Screen[10]

- Mining Feeder[3]

- Other Metallurgy Machinery[8]

- Drying Equipment[3]

- Other Refrigeration & Heat Exchange Equipment[2]

- Sand Washer[2]

- Mineral Separator[2]

- Construction Machinery Parts[1]

- Cement Making Machinery[10]

- Used Mining Machinery[1]

- Contact Person : Ms. Zhou Christina

- Company Name : Henan Zhongke Engineering & Technology Co., Ltd.

- Tel : 0086-371-67898596

- Fax : 0086-371-67898596

- Address : Henan,Zhengzhou,Weat Huagong Road

- Country/Region : China

- Zip : 450000

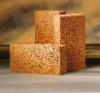

spinel bricks

Detailed Product Description

Spinel brick are mainly used in burning zone, transitional zone and kiln mouth of rotary kiln. In particular, Spinel brick has been becoming one of the major lining materials for rotary kiln. It is applied in the transitional zone, cooling zone, kiln mouth and even in burning zone of ceramic kiln. Spinel brick is replacing magnesium chrome bricks step by step. The thermal shock resistance of alkalescency refractory material is poor. The key point of using alkalescency refractory material is that a coating can be formed on surface of kiln. The shortcoming of poor thermal shock resistance can be made up by keeping the proper thickness of coating on kilnThat is 200 to 300mm It s also applied for spinel brick when it is used in burning zone of kiln.

Index | Fued synthetic Spinel bricks | sintering synthetic Spinel bricks |

MgO/%≥ | >78 | >80 |

Al2O3/%≤ | 10~13 | 8~12 |

Fe2O3/% | <1 | <1 |

SiO2/% | <1.8 | <1.5 |

volume density /kg.m-3 | ≥2920 | 2920~2950 |

Apparent porosity %≤ | ≤19 | 17~19 |

Compress strength /MPa≥ | ≥40 | ≥40 |

refractoriness under load , ≥ T0.6 | ≥1650 ≥1700 | ≥1650 ≥1700 |

Linear expansivity /% (1000) | 0.96 | 0.99 |

thermal conductivity /W (m K ) -1 | 3.00 | 3.00 |

Thermal shock resistance | ≥8 | ≥8 |